Description

Applications

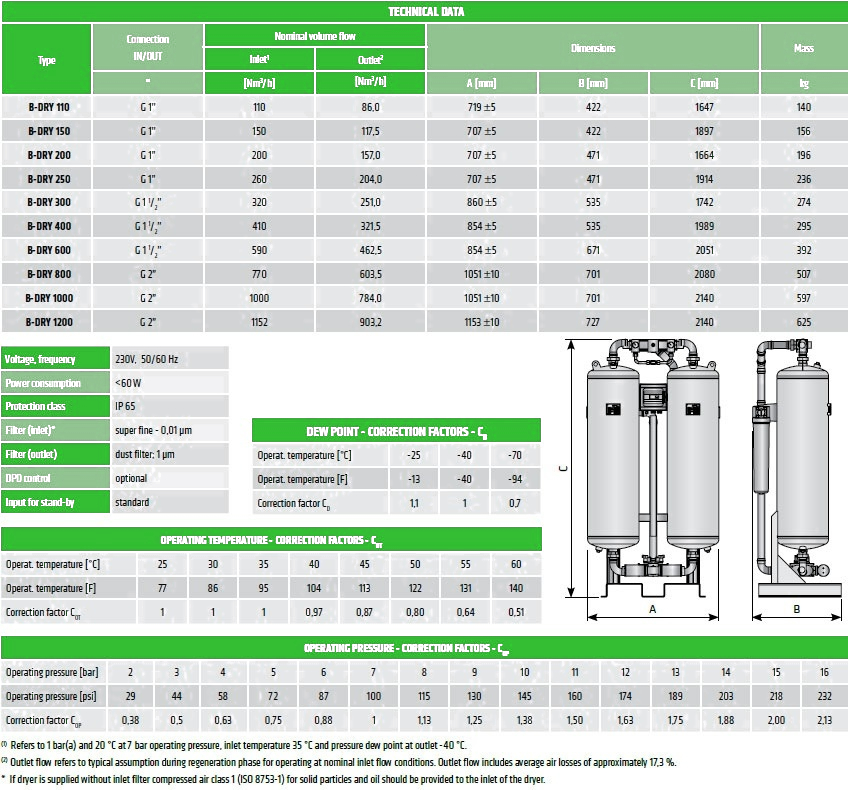

Heatless regenerative adsorption air dryers B-DRY, designed for continuous separation of water vapour from the compressed air thus reducing the pressure dew point.

About Heatless Regenerative Adsorption Dryers

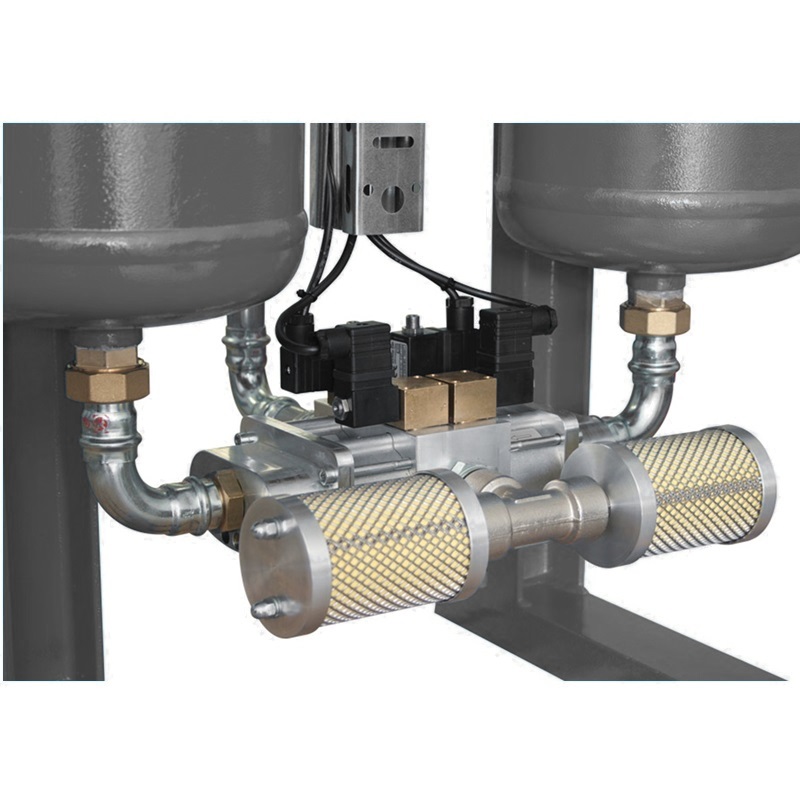

B-DRY series dryer consists of two columns, filled with desiccant beds, controller with LCD display, valves, manometers, support construction and suitable filter housings with the required filter element.

Adsorption takes place under pressure in the first column while the second column regenerates with a portion of already dried compressed air at ambient pressure. Immediately once the first column is saturated to a certain level, column switch-over is carried out and the process of adsorption continues in the second column. This occurs without any drop of pressure at the outlet of the dryer. Regeneration of saturated desiccant is possible because a small portion of already dry compressed air is decompressed and when expanded it becomes extremely dry. This portion of extremely dry decompressed air also called “purge air” is then fed through the saturated column in the reverse flow direction in order to remove the adsorbed water molecules from the desiccant and release them back to the ambient.

National Filters do also offer alternative heatless regeneration adsorption dryers that are geared up for smaller applications ideal for flow rates between 6 to 200Nm³/h(Click here) .

With years of expertise under our belt, National Filters is your go-to source for industrial solutions. We have pride in providing customised, high-quality solutions that we tailor to meet your specific needs. Let our team assist you today in finding the perfect compressed air dryer that will suit your requirements.

For more information get in touch with your National Filters Representative. sales@nationalfilters.com.au

Call 1300 DRY AIR (1300 379 247)