Description

Applications

The A-DRY desiccant adsorption dryer effectively separates water vapor from compressed air, lowering the dew point within the system. These dryers work particularly well in outdoor environments where freezing poses a risk, as well as in applications with stringent air dryness standards (PDP < +3°C). Industries such as food and beverage, pharmaceuticals, electronics, and chemicals rely on this technology for process air. Among the various types, heatless regeneration adsorption dryers stand out for their simplicity, reliability, and cost-effectiveness.

The Heatless Absorption Compressed Air Dryer

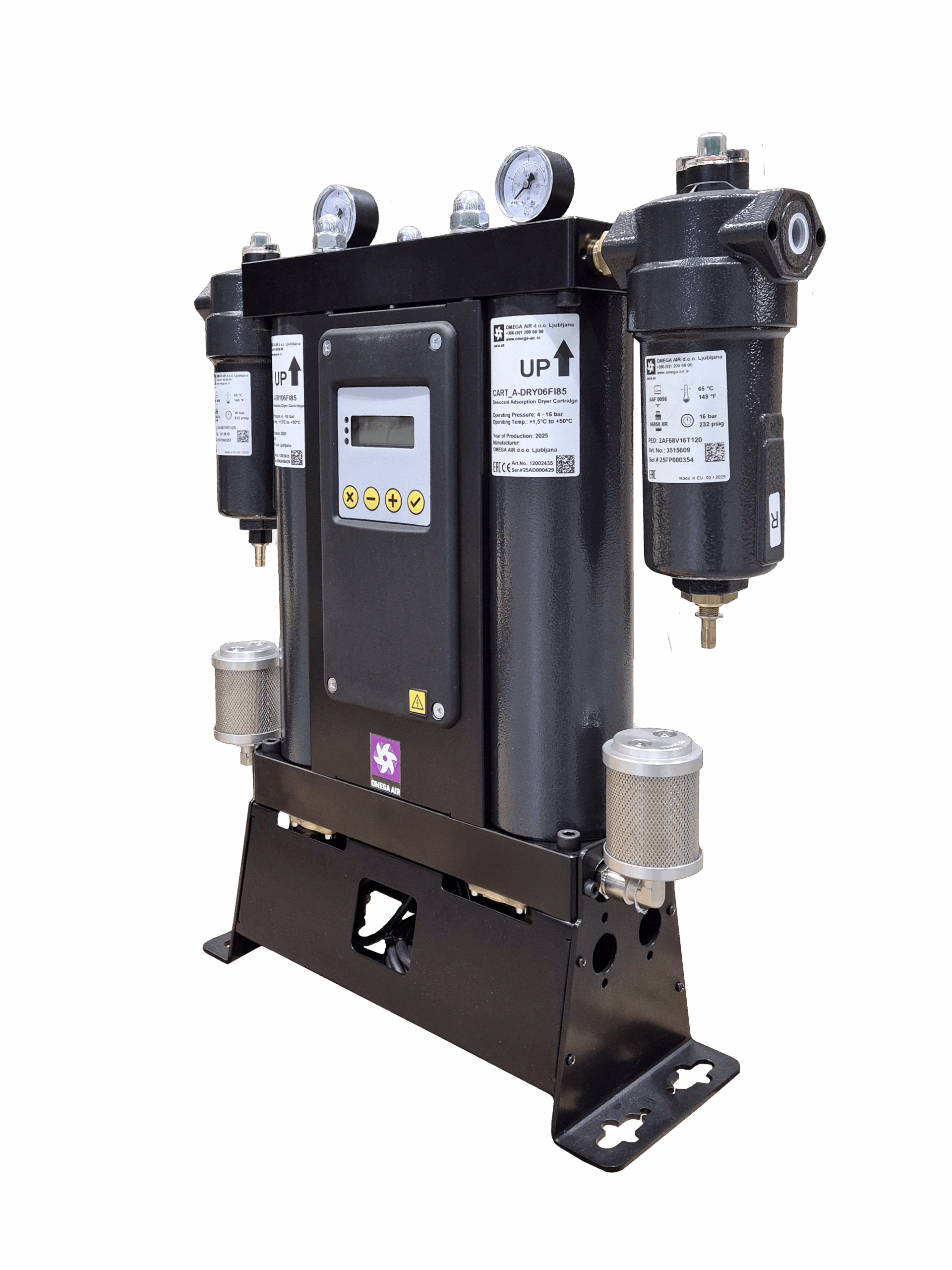

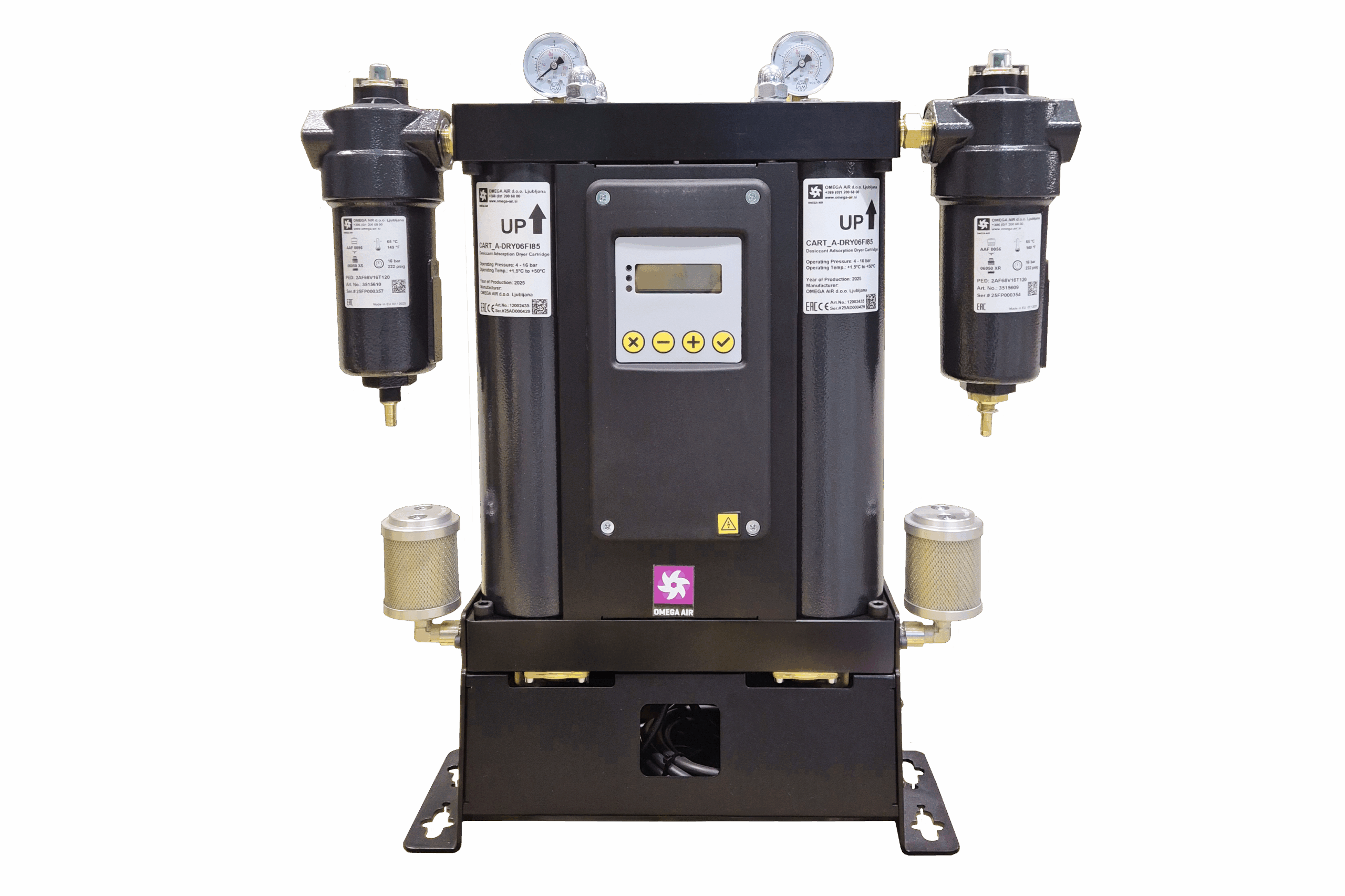

The Compact A-DRY series dryer features an upper and lower control block, a controller with an LED display, and two desiccant-filled columns that operate alternately. In the first column, the system adsorbs moisture under pressure; however, while this occurs, the second column regenerates using a portion of pre-dried compressed air at ambient pressure.

When the first column reaches a designated saturation level, the system seamlessly switches to the second column. This transition is crucial as it maintains the continuity of the adsorption process without experiencing any pressure drop at the dryer’s outlet. Consequently, the saturated desiccant regenerates by utilising a small volume of already dried compressed air, which decompresses to an extremely dry state.

Furthermore, this highly dry decompressed air, known as “purge air,” flows in reverse through the saturated column. As a result, it effectively removes the adsorbed water molecules from the desiccant, thereby releasing them back into the ambient environment.

Additionally, the new innovative design of A-DRY adsorption driers, created with our customers in mind, allows for quick and dependable installation, usage, and maintenance. Our plug-and-play controller simplifies the installation process, while reducing the number of components and steps needed for assembly and disassembly ensures efficient and reliable servicing.

Operating cycles

Fixed Cycle Mode

The timer regulates the transition between columns. By employing high-quality adsorbents and advanced control techniques, we successfully extended the adsorption cycle to 10 minutes. This enhancement leads to fewer switchovers, decreased compressed air consumption, and reduced wear on critical components.

Adsorption = 5 min

Regeneration = 4 min

Pressure build up = 1 min

Variable Cycle Mode (Switching Based on Dew Point)

By connecting a dew point sensor to the controller, the duration of adsorption can be prolonged according to the sensor’s readings, while regeneration can be completed in just 4 minutes. Opting for the variable cycle mode when operating the dryer can significantly reduce average purge air consumption to exceptionally low levels, possibly even below 3%.

Standby Mode in A-DRY Series Heatless Adsorption Dryers

A feature of A-DRY series adsorption dryers allows them to receive a standby signal from the compressor or another compressed air source. In standby mode, air can freely flow through both towers from the inlet to the outlet of the adsorption dryer. Simultaneously, the adsorption dryer controller is in standby mode and poised to return to normal operation upon receiving the appropriate signal. The standby signal is transmitted to the A-DRY adsorption dryer via a standby contact on the controller using a connected switch.

Easy Maintenance

Thanks to the innovative column design, replacing desiccant can be completed within minutes. The entire column can be easily removed from the dryer by loosening four top nuts and removing side locking screws. This allows for refilling or replacing the column with a new one. Removing the column provides easy access to the check valve and purge nozzle without having to disassemble the entire adsorption dryer. Valves and membranes are situated beneath the lower control block, enabling quick and simple access for replacement.

National Filters do also offer alternative heatless regeneration adsorption dryers that are geared up for larger applications ideal for flow rates between 110 to 1152Nm³/h (Click here)

National Filters is here to assist you in assessing your business goals and selecting the ideal air compressor dryer solution to meet your specific needs and requirements.

For more information get in touch with your National Filters Representative. sales@nationalfilters.com.au

Call 1300 DRY AIR (1300 379 247)