Heat Recovery Unit

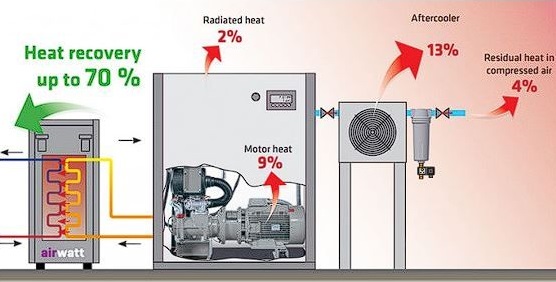

In traditional screw compressor systems, the lubricating oil is air-cooled, with excess heat expelled into the surroundings by a fan, resulting in total heat loss. To address this inefficiency, the AIRWATT external heat recovery unit was developed to effectively harness the wasted heat produced during air compression in rotary screw compressors. This recovered heat, often exceeding 70% of the energy consumed by the compressor. As a result this could be utilised to heat household water or provide heating at minimal additional costs. Not only does this strategy save money, but additionally it also promotes environmental sustainability.

The AIRWATT External Heat Recovery Unit features two distinct piping systems operating in counterflow. Heat exchange between the compressor and sanitary water takes place in a plate heat exchanger, where the compressor oil and sanitary water converge. Additionally the unit is equipped with a thermostatic valve to regulate temperatures, preventing the compressor system from becoming too cold and sustaining damage.

Characteristics

Heat Recovery

On the back side of the device, there are four connections. Two of these connections link to the compressor oil circuit, while the other two are related to the water circuit. During compressor operation, the compressor oil flows continuously through the AirWatt heat exchanger oil piping and plate heat exchanger. Initially, water does not flow through the thermostatic valve until the oil temperature meets the valve’s configured value. Once the oil temperature reaches the desired level, the thermostatic valve opens, allowing water to circulate through the plate heat exchanger. As the oil releases heat and cools down, the water absorbs heat. The temperature of the water at the outlet rises as the flow rate decreases.

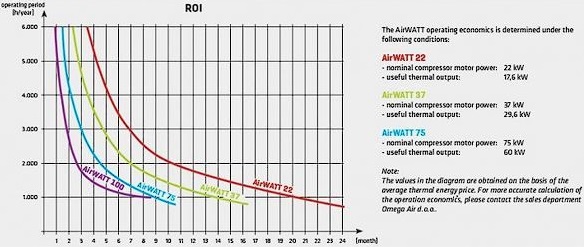

Investment Payback Period

Data Sheet Heat Recovery AirWatt v2.10

For more information get in touch with your National Filters Representative. sales@nationalfilters.com.au

Call 1300 DRY AIR (1300 379 247)